Product categories

Chemical process pump

Release time:2014-05-07 09:56:01

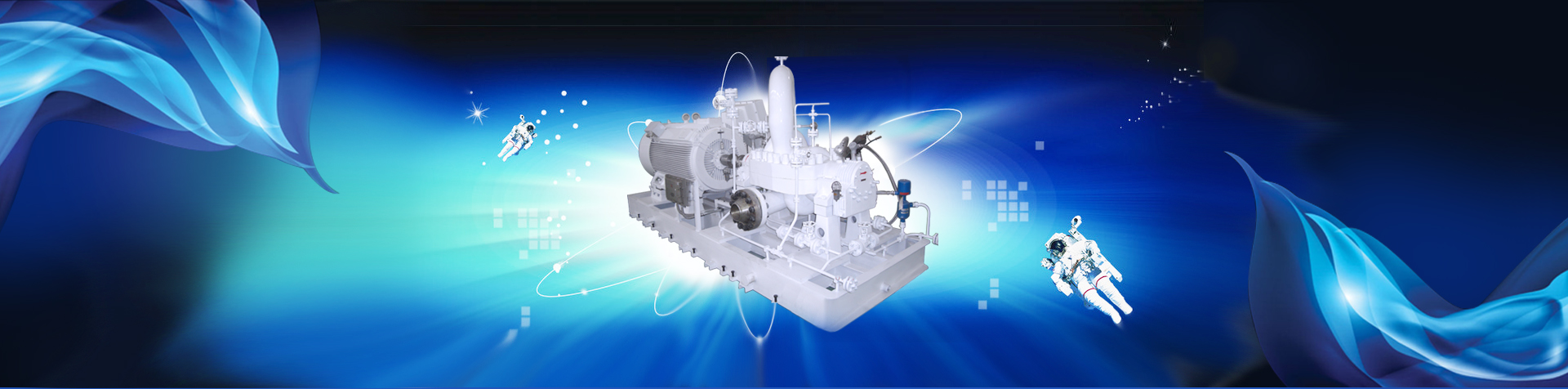

Product Overview

HTE Petrochemical centrifugal process pumps is designed and manufactured according to API610 specification by our company. Our company has obtained the quality system certification of API 610 , and in product design , manufacturing and so the whole process of the establishment of a strict quality control system, product quality have fully reliable protection.

Applications

This series pumps are suitable for pumping clean or slightly contaminated with no solid particles, neutral or slightly corrosive liquids. This series pumps are mainly used in oil refining , petrochemical, chemical industry , coal chemical industry, paper industry , marine industry, power industry as well as food , pharmaceuticals, environmental protection and other industries.

Performance range

Speed (N): 2950rpm and 1475rpm

Pressure (P): Suction Flange pressure rating 5.0MPa (HTE) / 2.5 MPa (HTA)

Flow rate (Q): ~ 2600m3 / h

Head (H): ~ 250m

Operating temperature (T): -45 ℃ ~ +450 ℃ (HTE) / -45 ℃ ~ +150 ℃ (HTA)

Product Features

1. The structure is safe and reliable, the operation of the pump is stable.

2 The pump have high average efficiency, low energy consumption, is the ideal choice for energy-saving products.

3 Cavitations performance is unmatched with similar products of other companies. with minimal cavitations margin value of many products can be as low around 0.5m. Due to the low NPSHr value petrochemical plant installation height can be reduced, saving investment.

4. The pump has very broad performance range. Flow rate (Q) can be up to 3000m3 / h, head (H) can be up to 230m, and the flow and the head of pump are closely spaced, which provided the convenience for user to select pump.

5. Cooling type of bearing has air cooling, fan cooling, water-cooling, the three types can be selected depending on the temperature of the pump. Fan cooling is particularly suitable for no water or poor water quality in some region.

6. High degree of standardization, good commonality, reduce largely inventory of user spare parts.

7. The hydraulic components of pump select material refined, according to working conditions, what material to choose is completely determined by the user.

8. The axial force of the series pump was balanced by wearing ring and balance hole, residual axial force was born by thrust bearing.

9. The discharge more than DN80 double volute casing design structure to balance the radial force , thereby reducing pump noise , bearing life has been extended.

10. Use of dry -type shaft design, is completely isolated from the medium, to avoid corrosion of the shaft, so that the overall life of the pump is improved.

11 Impeller can have open, semi-open type, with replaceable wear plates of casing front and rear, for conveying containing particles, slurry and a variety of media with viscosity.

12 Wearing part of this series pump is wearing ring, sleeve and some small parts and so on, so you can resume normal performance after the replacement of wearing parts, save operating costs.

13 Pump casing is the draw-out design, meanwhile with motor adopt extended membrane couplings, and pump maintenance, piping and electrical Needless to disassemble, repair and maintenance quick and easy operation.

14 Packing seal or mechanical seal machine can be adopted.

15. Pump seal and auxiliary flush plan in accordance with API682 configuration to ensure the reliability of the pump seals in different conditions.

友情链接

- China aerospace science and technology group co., LTD

- Institute of aerospace propulsion technology

- Shaanxi aerospace power technology co., LTD

- China national petroleum corporation website

- China petroleum and chemical group co., LTD

- Baoji aerospace power pump industry co., LTD

- Jiangsu aerospace hydraulic equipment co., LTD